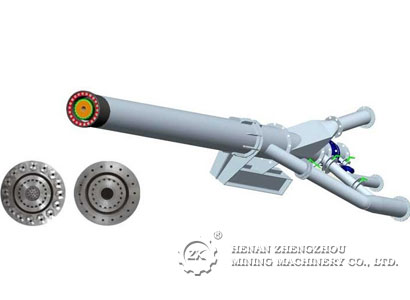

| Message: | Multifuel burner is a new combustion device burning gas and coal powder in rotary kiln. It has a unique structure and reasonable parameters to ensure gas, coal powder and air, primary air and secondary air mixed sufficiently. It brings greater thermal intensity, higher combustion efficiency and easier adjustment. It can be widely applied to various rotary kilns in metallurgical and chemical industry.

The burner can mix gas and coal powder for co-burning, and also can realize gas or coal powder separate burning.

Application:

The rotary kiln’s combustion system in electricity, chemical, metallurgy, building materials industries.

Our products advantages :

1. Flame stable, no fluctuation, no flame sweeping kiln lining and prolong kiln lining life;

2. Reasonable structure design, well mixed gas and coal powder, primary air and secondary air, complete combustion, can improve the kiln thermal strength while reducing the proportion of primary air to improve the productivity of the kiln and reduce heat consumption;

3.The flame round up cover forms bowl effect and initial flame without strong eddy. It avoids temperature peaks and distributes the flame temperature rationally. This can effectively protect the kiln body and guard plate.

4.Due to fully mixing between air and coal powder, the combustion is more efficiency. It can reduce the content of CO and NOX in exhaust gas and be beneficial to safety and environmental friendly operation.

|

my account

my account

log out

log out

my account

my account

log out

log out